In today’s fast-paced world, our planet is increasingly facing the challenge of sustainability. This has led to a need for an alternative approach that not only conserves resources but also protects the environment. With the advent of 3D printing, a new era of innovation has begun. This technology has revolutionized manufacturing, enabling us to create sustainable objects using various materials in 3d printing.

The environmental impact of additive manufacturing has been under scrutiny, and it is no secret that 3D printing has some eco-friendly advantages. First and foremost, 3D printing significantly reduces the waste produced during the manufacturing process. Traditional manufacturing techniques can leave up to 30% of waste materials. However, 3D printing significantly reduces this amount, as the process essentially makes use of only the amount of material required to produce the object. Therefore, by using materials in 3D printing, you could save significant amounts of resources, resulting in a more sustainable, eco-friendly approach.

Another advantage of 3D printing is that it eliminates the use of conventional molds and dies that manufacturing plants have relied on for decades. These molds and dies are made from metal, which is a non-renewable resource that requires significant energy consumption in production. Materials in 3D printing offer multiple sustainable advantages as they are made of biodegradable materials such as corn starch, potato starch, and cellulose. Which reduces the carbon footprint and eliminates waste.

3D printing takes sustainability a step further by providing a way to ‘print-on-demand.’ This means products only get created when they’re needed, reducing the impact of transportation costs and packaging waste. This is especially significant in industrial manufacturing, supply chain management, and mass production.

Moreover, the 3D Printing system offers a platform for businesses to adopt significant changes to the materials they use in their production processes. New materials in 3D printing such as recycled plastics, eco-friendly resins, and biodegradable materials significantly reduce the environmental impact of manufacturing. This can influence the entire supply chain process, from suppliers and manufacturers to retail suppliers and the end consumer.

In conclusion, materials in 3D printing offer a sustainable path to create sustainable objects with minimal environmental impact. Its ability to print-on-demand, use 100% recycled materials, and eliminate waste makes it a game-changer in the battle against climate change. Although the process of 3D printing can be energy-intensive, the benefits far outweigh the costs of conventional manufacturing. By using materials in 3D printing and embracing sustainability, we can make our world a better place and create a brighter future for generations to come.

Publisher Details:

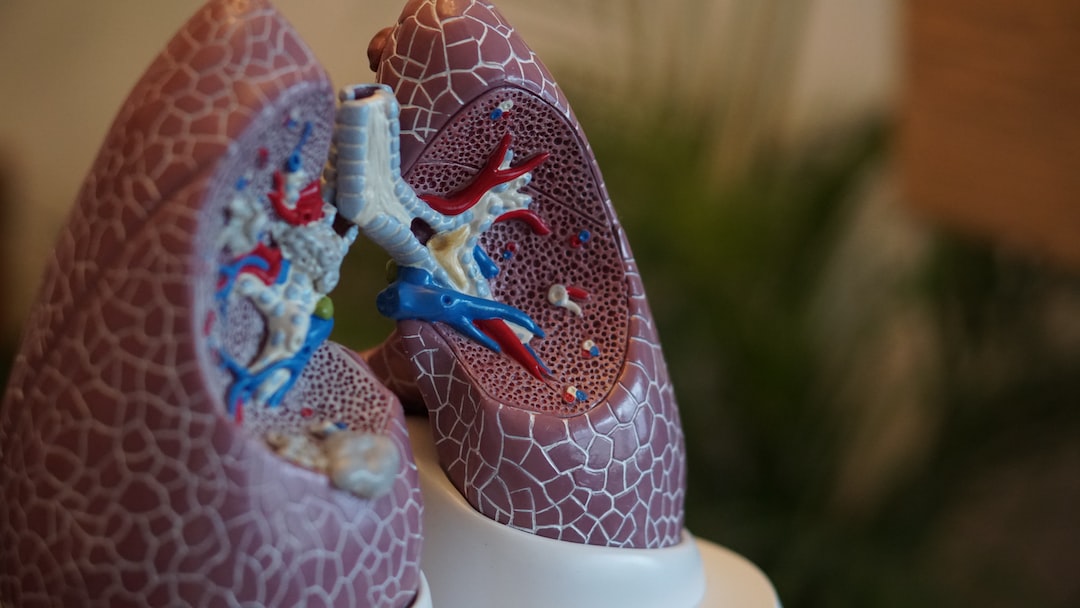

3D Printed Bone Implant | Biomaterials | NOVUS Life Sciences

https://www.novusls.com/

In NOVUS, we research and develop varieties of biomaterials for medical and veterinary uses. From the chemical building blocks to the products that can be used in surgeries, NOVUS has put tremendous resources in serious researches and productions. Since founded in 2014, NOVUS has grown into a hub of biomaterials with great interests in pushing forward the advancement of material sciences to change the world.