The Role of Artificial Intelligence in Smart Manufacturing Systems

In recent years, we have witnessed a significant rise in the use of artificial intelligence (AI) in various industries, and one sector that has greatly benefitted from its integration is manufacturing. Smart manufacturing systems, powered by AI, have transformed the way products are designed, developed, and produced. This technological revolution has resulted in increased productivity, efficiency, and cost-effectiveness, making it a game-changer for the manufacturing industry.

AI has revolutionized the entire manufacturing process, starting from product design. AI algorithms can analyze vast amounts of data to identify patterns and make accurate predictions about consumer demand and market trends. This enables manufacturers to tailor their product designs and features according to customer preferences, giving them a competitive edge in the market. By leveraging AI, companies can quickly adapt to changing consumer demands and gain a deeper understanding of their target audience. This not only improves customer satisfaction but also reduces the risk of producing unwanted or obsolete products.

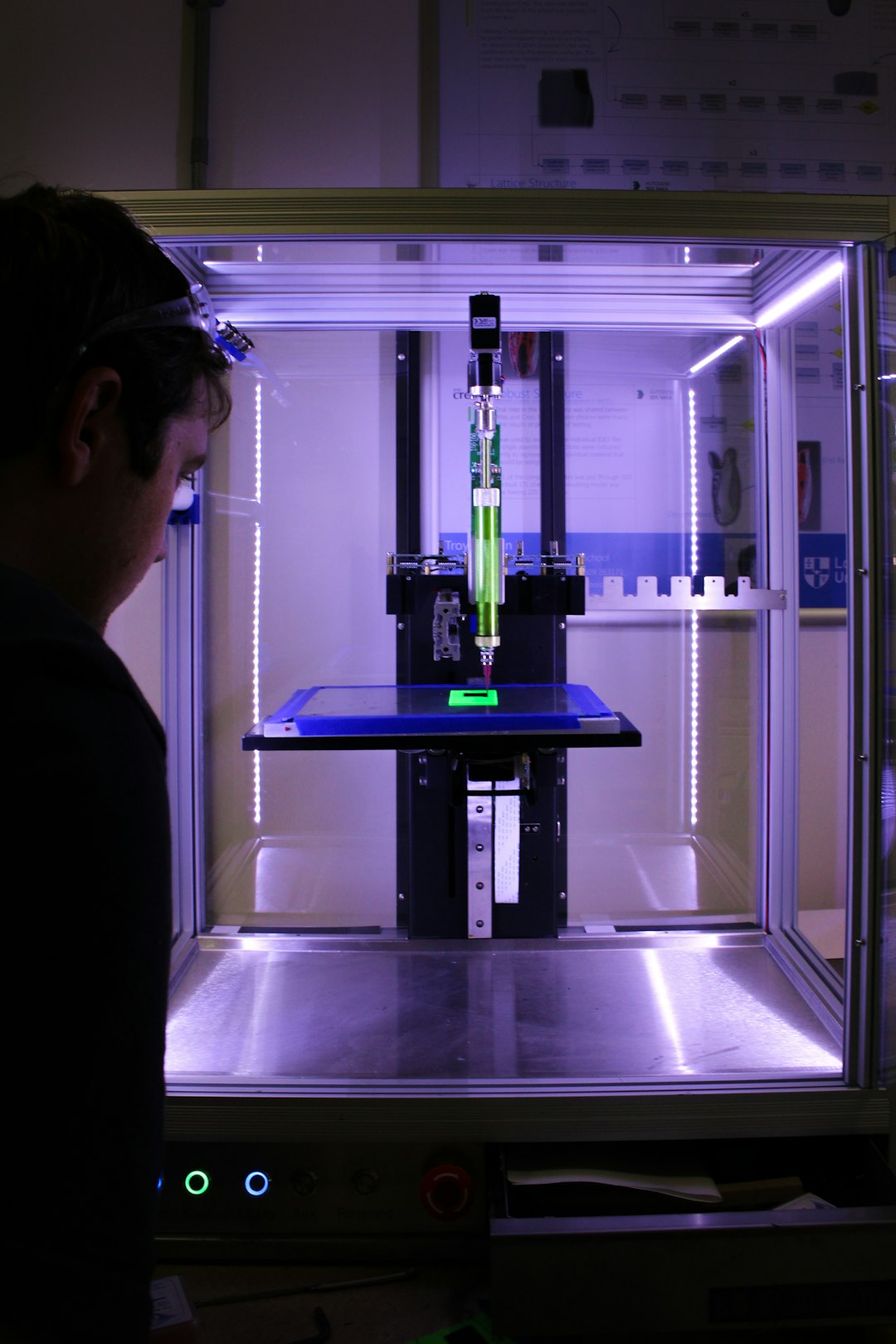

Once the designs are finalized, AI plays a crucial role in optimizing the manufacturing process itself. Traditional assembly lines often face challenges such as bottlenecks, delays, and high error rates. However, by integrating AI, manufacturers can automate various tasks, reducing human errors and increasing production efficiency. AI-powered robots and machines can handle repetitive tasks with precision and accuracy, resulting in higher output levels and better quality control.

AI can also monitor and analyze the production process in real-time. By collecting data from sensors and IoT devices located throughout the manufacturing floor, AI algorithms can identify issues and bottlenecks before they become major problems. This proactive approach allows manufacturers to take corrective measures promptly, minimizing downtime and maximizing productivity.

Furthermore, AI can optimize the supply chain management system, ensuring that manufacturers have the right resources at the right time. By analyzing historical data, market trends, and other variables, AI algorithms can predict future demand and optimize inventory levels accordingly. This reduces costs associated with overstocking or understocking and ensures an uninterrupted flow of materials throughout the production cycle. AI can also optimize logistics operations, enabling manufacturers to improve delivery times and enhance customer satisfaction.

Another area where AI is making a significant impact in smart manufacturing systems is quality control. Traditional quality control methods involve manual inspection, which is time-consuming, labor-intensive, and prone to human errors. However, with AI-powered computer vision systems, manufacturers can automate the inspection process, significantly improving accuracy and efficiency. AI algorithms can analyze images and videos captured by cameras to detect defects or anomalies, ensuring that only products of the highest quality reach the market.

In addition to enhancing the manufacturing process, AI is also transforming maintenance operations. By analyzing real-time sensor data, AI algorithms can predict the lifespan of critical components and schedule maintenance activities accordingly. This predictive maintenance approach minimizes the risk of unexpected equipment failures, reduces downtime, and extends the lifespan of expensive machinery.

Moreover, AI can enable manufacturers to achieve energy efficiency and sustainability goals. By analyzing energy consumption patterns, AI algorithms can identify areas of high energy consumption and suggest optimization strategies. This not only reduces costs but also minimizes the environmental impact of manufacturing operations. AI can also help in waste management by optimizing resource utilization and recycling processes.

However, it should be noted that the integration of AI in smart manufacturing systems also raises concerns about job losses and the impact on the workforce. While it is true that the automation of certain tasks may result in job displacement, AI also opens up new employment opportunities. As AI takes over repetitive and mundane tasks, human workers can focus on more complex and creative tasks that require problem-solving skills and critical thinking. Additionally, the development and maintenance of AI systems require a skilled workforce, creating job opportunities in the field of AI and robotics.

In conclusion, the role of artificial intelligence in smart manufacturing systems cannot be overstated. From product design to quality control and maintenance, AI has transformed the manufacturing industry, enabling companies to achieve higher levels of efficiency, productivity, and cost-effectiveness. Moreover, AI can empower manufacturers to be more customer-centric, responding to market demands quickly and accurately. While challenges exist, the integration of AI in smart manufacturing systems promises a brighter future for the manufacturing industry.